John Wilson Tumbling Instructions by John Wilson

Editor opinion:

For those of you who don’t know, John Wilson tumbled bottles as his full time job for over a decade. He knows what he's talking about and nobody can do a better job. He is so good people call bottles he has polished, "Wilsonized". If you have been cleaning your own bottles or if you intend to, take heed. I've seen some bottles of extreme rarity that were tragically over cut or over polished. My advice is, go easy tumble at slower speeds with less polish for a shorter period of time, or follow John’s instructions to the letter. DO NOT OVERCUT!

John says about cutting with aluminum oxide or any other cutting agent, ”Run on outside for a maximum of six hours.” It’s no joke, when cutting LESS IS BETTER! You can always re polish the bottle if you want. You can't go back and put the mold seams on or redo the embossing or put back the individual characteristics the mold left on the glass. A bottle with case wear and scratches is better than a bottle with no case wear, no scratches, no mold seams, reduced embossing and the overall soapy haze that over cleaned bottles have. When you over tumble you reduce the value of your bottle and alter an antiquity that it is your responsibility to preserve.

Thanks, Steven

LOADING INSTRUCTIONS

- Pour copper into bottle.

- Turn bottle horizontally and shake until copper is level.

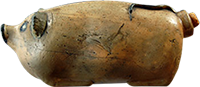

- Remove or add copper until bottle is half full as in fig. #1.

- Turn bottle upright and shake until copper is level.

- Pour compound slurry into bottle until copper is covered over ½” as in fig. #2.

- Plug or tape mouth of bottle.

- Wrap with foam or cloth until it fits snugly into the cylinder.

- Put caps on the cylinder.

- Put cylinder on machine and run for 3 to 6 days.

- Rotate cylinder halfway through the run when doing multisided items.

OUTSIDE LOADING

- Put bottle in cylinder making sure it is centered and sitting on all of the prongs.

- See fig. #3.

- Fill cylinder ½” to ¾” full of copper. Longer necked bottles require more copper. This process takes a little practice to get right every time.

- Cover copper with slurry.

- Take the plug apart.

- Seat stopper and bottom part of the plug into the mouth of the bottle.

- Assemble the rest of the plug and tighten the nut while pushing down on the plug to keep the bottle seated.

- Use a nut driver or socket wrench.

- Run for 3 to 4 days.

- Rotate tube halfway through the run for sided items.

USING THE ALUMINUM OXIDE

- P30 or 12 micron mix 1 tablespoon with 10 oz. water. 3 micron mix, 1 teaspoon with 10oz. water.

- Mix slurry per instructions.

- 12 micron: Cover copper with slurry run on outside only for maximum of 6 hours.

- Rotate after 3 hours if doing sided items.

- When done, remove bottle and wash the bottle, tube and copper.

- The bottle should appear frosted.

- Replace bottle and copper and cover copper with P30 slurry.

- Run for 3-4 days.

- 3 micron: Used as an inside cutter only. Run for 4-5 days. When done if the inside of the bottle appears to be a little hazy, rerun with P30 for a few days.

OTHER HELPFUL HINTS

When using the machine for the first time don't use an expensive bottle. Use cheap items until you are comfortable with the process. When doing any kind of polishing, make sure all dirt is removed from the bottle. One particle of sand will permanently scratch a bottle. Make sure your copper is kept free of contaminants. Make sure the slurry is shaken just before use. It will settle quickly. Once inside the tube or bottle, settling is OK. When it is run it will be stirred enough.After the run is done, pour slurry and copper into a fine strainer and rinse with warm water. The copper is reused over and over. Just don’t lose it down the drain. If the neck and top of the bottle don’t come clean on the outside, add more copper. Use liquid toilet bowl cleaner to remove compound residue from the bottles. An old toothbrush works great to scrub the slurry off of the outside. Put cleaner, water and some copper in the bottle. Shake and rinse inside until clean.